It’s been a few days since we got back but it’s only now that I have the mental energy to do a post (don’t really have the time but here it goes anyway).

The second test day went fairly smoothly. The usual setup in the dark, run at first light. Some photos from testing are here.

Again Rodney and Jonathan took turns driving. Both took it fairly easy, especially Rodney holding back quite a bit since it’s not his car. This paid off – on one of his runs he saw a deer near the apex of an upcoming corner and was able to brake early enough to avoid the animal dashing across the road at the last moment.

Nevertheless both did well relative to our competition. This is encouraging. We also learned a few more things about our fuel usage, tire pressures, shock settings and a host of other things. Overall a good and productive test. We drove up afterwards since I hadn’t been to the top on this trip yet. Still quite a bit of snow but it’s melting fast.

The trip back was long but uneventful. One change we made from last year is not driving in the dark, when chances of wildlife encounters are greatest and fatigue the highest. In daylight we can take in some cool scenery along the way.

Upon return to the shop, a flurry of activity (and Tristan has been working nonstop while we were gone). Dropped off the D2RS body panels for paint, picked up the molds, dropped off other molds, finalized paint scheme, and so on.

The main color will be Porsche Lava Orange, with nose liner and some trim in basic grey. The paint is getting applied today and we’ll start putting panels back on the car tomorrow.

In the meantime we’ve reinforced suspension pickups and replaced all bolts with brand-new ones. The bolts are designed to shear in a crash providing energy absorbtion so we want to maintain that feature. The new big brakes, sticky Hoosier tires and Jonathan pushing the car harder combined with what appears to have been a flaw in one of the bolts caused a failure in testing. The solution is a double-shear setup using a weld-on bracket and an aluminum endplate. This is actually the production setup on the current cars but wasn’t incorporated in this earlier chassis. Now it is. We’ll re-powdercoat the whole thing after the race, when some other mods for adding the top are done.

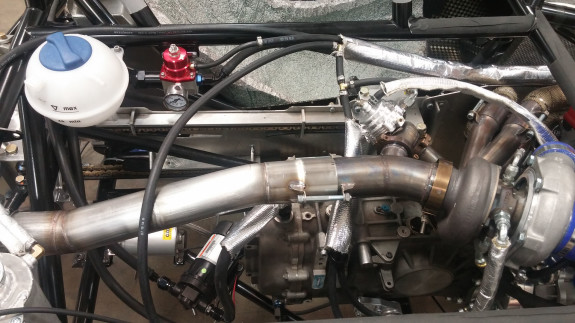

On the D1PPS front, things have been moving along. As of mid-day yesterday all the plumbing was in place, dash fabricated, wiring was in progress and we were starting to fill fluids.

Later in the aftenoon Tristan was in the process of adjusting and bleeding the clutch when suddenly I hear a lot of swearing. Not a good sign. There is clutch fluid everywhere – the slave piston overtraveled and popped out of the bore. We now have to take everything apart and figure out why. If you look at the May 31 entry in our 2015 blog, you’ll see we had the opposite problem with the D2RS – clutch clearance started out fine but then the spring came back to where clutch wouldn’t engage, and we had to remove a spacer and then do some machining to provide more room. The clearance for the D1PPS setup was measured with no plates in the clutch, it’s the furthest the spring fingers can come back and the release bearing was placed accordingly. Turns out that in this setup once the plates are in, the fingers come a ways forward. The throw on the low-profile slave is only 0.7″ and in this case we’ve exceeded it. Lots more work now. Still, it’s better to find this out here and now than on the Mountain.

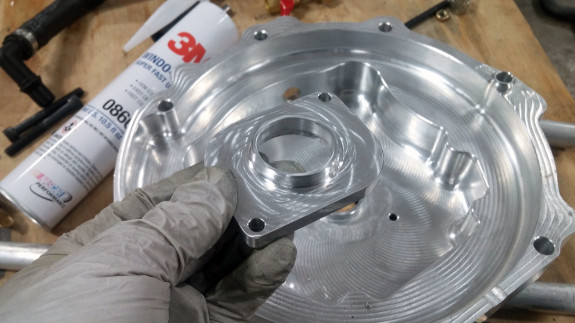

All the fittings come off, the engine is separated from the gearbox and we are able to slide it forward enough to take apart the bellhousing without fully removing the motor. This takes about 1.5 hours.

After much measuring and double checking I end up machining a 0.3″ spacer that should put us where we need to be. The clutch is a cerametallic one and in our past experience with the D1 hasn’t come back nearly as much as the one in the D2RS. Worst case the spacer is something that can be removed later, and we know that without it the clutch will definitely have clearance even if fully worn. But the plan is to have everything work with the spacer in place. From discovering the problem to having everything taken apart, measured, spacer designed and machined is 3.5 hours.

It’s now 9 pm and the reassembly will happen tomorrow. Overall servicing the release bearing is about a 4-hour job. Doable after a morning test if need be but let’s hope it’s not needed. We’ll bring an alternative 0.125″ spacer with us just in case. Now back to wiring, the rest of the fluids, and a thousand other tasks. We have ORP booked for testing both cars on the 15th and 16th for which Jonathan is flying up from California. Plan is to leave for the race on the 18th early AM. Pete (the D2RS owner and long-time customer) has agreed to lend us his truck and trailer, since both cars won’t fit into ours. We’re on a path.