D1PPS

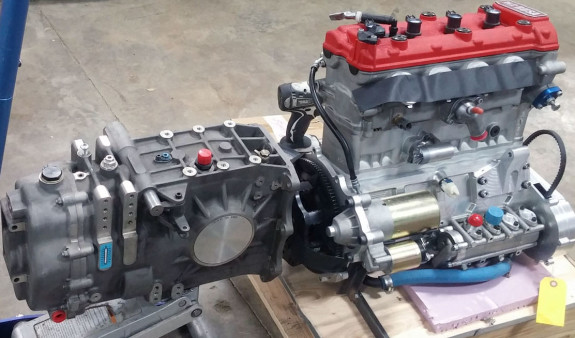

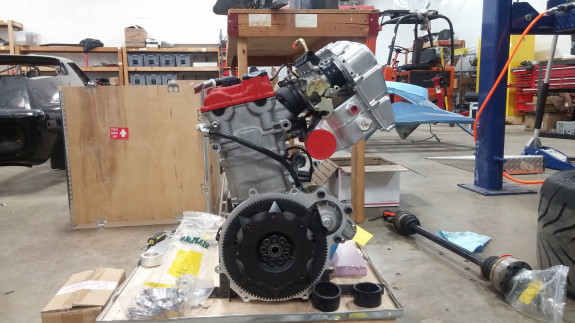

There’s much building to do on the D1PPS. One area is the drivetrain. The engine is now back from Hartley. The old crank was sent along with it and is a good illustration of why I wanted to upgrade it. Being a modified stock Hayabusa crank, it still has the power take off and counterbalancer drive gears, and of course the welded flywheel mount.

Compare to the new one from a picture posted earlier. New part is stronger, lighter, has bigger bearings and provides for larger displacement. All wins.

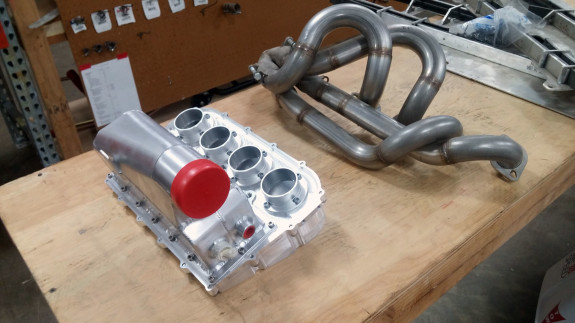

The turbo and parts like wastegate and blow-off valve are due to arrive in the next couple of days. In the meantime I’m getting ready to machine the bellhousing and checking the dimensions for clutch and release bearing one more time. Material is already here, just need to finish programming and start making chips.

When the turbo and pieces arrive we’ll finalize the intake and exhaust plumbing, then put the whole thing on a dyno.

Other things in progress are the suspension pieces. Weld-in inserts for the suspension arms are done. Of course the uprights, bellcranks and many other parts are already on the inventory shelf, having been made earlier. Suspension boxes are next.

One of the challenges is that the parts we need to machine now are among the largest we’ve attempted inhouse and will really push the limits of what our machine is capable of. More on that soon. In the meantime the D1PPS bodywork is being painted and wings are being made. Time is short and a lot is still to be done. For us, the race has already started.

D2RS

The main effort on the D2RS is in bodywork and we’re impatiently waiting for the first parts out of the molds. But there are other improvements planned too. Chief of them is an electronic paddle shift system for the sequential gearbox. In our experience with such systems, they really make a difference by letting the driver better focus on the strategy of the race with less attention spent on the mechanical tasks of operating the car. Of course there is no ready-made solution and we have to put it all together. Some experiments are involved and successful outcome is not guaranteed. The contingency is to run the mechanical shifter.

There are several pieces to the puzzle which are coming from different vendors. The brain of the system is the GCU (gearbox control unit). It looks at various inputs and controls the shift process by commanding pneumatic valves and other components to do the right thing at the right time. A blipper is a separate unit to trick the stock engine computer into thinking that the drive-by-wire throttle pedal has been pushed. Then there is the pneumatic shift actuator, the air tank and compressor, as well as assorted sensors. We’ve done paddle systems on our other cars but this one is unique enough to be a genuine development project. Nothing picture-worthy at this time but there will be as we progress.