Testing on the Mountain is now less than a week away. And we still don’t even fully know how we’re going to get there, if both cars are ready. Our normal trailer only holds one and our plan to have two custom trailers built by now has gotten only as far as having the custom axles made for both. Not zero but not close. So basically the plan is to cross each bridge just as we get to it, and improvise-adapt-overcome as need be.

Both cars have lots of stuff happening. Whether enough of it is happening fast enough, we’ll see in a couple days. For now all we can do is just push forward.

D1PPS

This is the one with most of the drama. George did get the engine running and mapped – having to replace a starter that failed and crank sensor wiring that shorted, but this is now a minor sidenote in comparison. To get a full appreciation of what has been achieved, keep in mind that two days ago it needed new block, pistons, and head – none of which were onhand at the time. He was going to be at Pacific Raceways today so I asked him to bring the engine there – saves me over 2 hours driving roundtrip. It was like a drug deal in the parking lot – I handed him a piece of paper, we opened the back of his van and mine, and transferred the goods.

After all the trials and tribulations, and my realization that our compression ratio is likely a couple points higher than expected due to longer stroke (confirmed), we decided to just stick with 10 psi. In order to finish first, one must first finish. And with ‘just’ 350hp, if we actually keep this all the way to the top, it will be our most powerful Pikes Peak car to date. Due to various technical and human issues, in 2012 we ran with about 180hp (in a slightly heavier 1,200 lb car) and in 2015 with about 290 in a much heavier 2,100 lb car. Both of those runs resulted in class wins, but we have potentially much faster competition this year. As always, nothing is certain and anything can happen on race day.

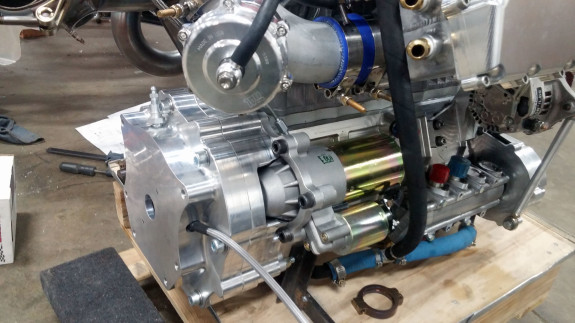

So I got the engine back to the shop and we’re now installing it. Bellhousing pieces seem to fit.

Initial install is encouraging as well. We already know we’ll have to cut a clearance hole in the bodywork for the intercooler, but it will be minimal.

Wiring is next, as well as a few plumbing fittings, paddle shift parts, and so on. If we had three weeks to do this, no sweat whatsoever. We have three days. Less monumental but still a challenge, we also have to figure out sponsor decals, etc. Some are already on.

D2RS

The bodywork fitting process is coming along. There are a few other items to take care of, but the body panels take center stage. And we have to make sure that they fit with wheels turned and such.

If we were at this point two weeks ago I’d be very happy. Now I’m anxious but hopeful. Hope doesn’t get things done though, work does. So that’s what we’re doing. Stay tuned.