The push continues. A while back we got a set of new Wilwood FSLR 6-piston calipers for the race car. All along we knew the fit was going to be tight but that it should generally work. Last week I finally did a quick mock-up on our demo D2, the only car that has the bigger rotors so far, and decided that the clearance to the wheel upfront is too tight. So we ordered a set of the regular 4-piston Dynapros and made arrangements to return the FSLRs.

Friday a follow-up call to Wilwood revealed that the Dynapros had not yet shipped. This being a holiday weekend, and with ORP testing coming up Thursday, that leaves us hoping that the new calipers can be overnighted on Tuesday and that we can put everything together Wednesday. Generally doable, but too much depends on factors not in our control. When Tristan threatened to take the brakes off the demo car to put on the race car, I needed another option. Which is to see if the FSLRs can be made to work afterall, maybe going as far as machining down the calipers themselves if need be.

If we had the luxury of time (and extra cash), there would be numerous possible solutions – from the simplest of waiting for Dynapros to show up to things like going to 18" wheels and tires upfront to clear the bigger calipers. However, time is the key missing part of this equation and that takes all the above off the table.

Saturday was spent finishing up the run of parts that were already on the machine and today I designed and made a prototype caliper bracket. This is where having in-house CNC (and being able to use it myself!) really pays off. I went from an idea and a scrap piece of billet to a functional part in about 3 hours total time. In the middle of a 3-day weekend. I strive to not let the outside world dictate my schedule, to the extent possible. Mission accomplished in this case.

Next step is to test-fit the bracket and the caliper on the demo. The original plan was to run the race car with new bodywork and therefore no wheel-mounted fenders. Now that having the new body in time is very much in doubt, I had to test the fender mount fit as well, which I knew was going to be a challenge. So the old caliper comes off and the new goes on.

So far so good. The fender mount required some minor clearancing but fit it does. Barely.

Now the real test – the wheel.

Yes! It does fit with about 0.2" to spare which is plenty. No need to modify the calipers even. And no need to take apart the demo. Which means we’ll be able to test the bigger calipers vs. the regular ones back-to-back Thursday. Brakes are very important on the Mountain (counter-intuitive given that you’re climbing 5K feet, but true). Having the extra margin of stiffer calipers and more pad volume is a good thing.

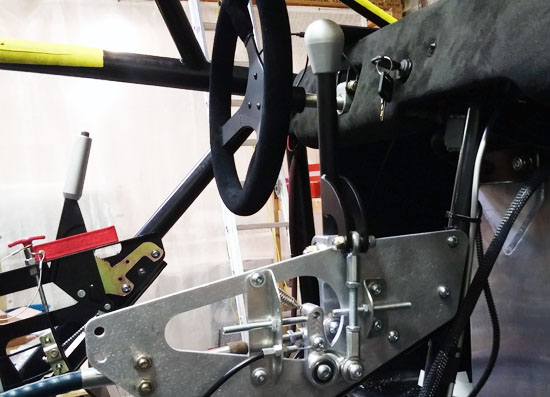

Other systems have been progressing in the meantime. Various plumbing bits, tweaks to the airbox and intake, wiring, shifter linkage, etc.

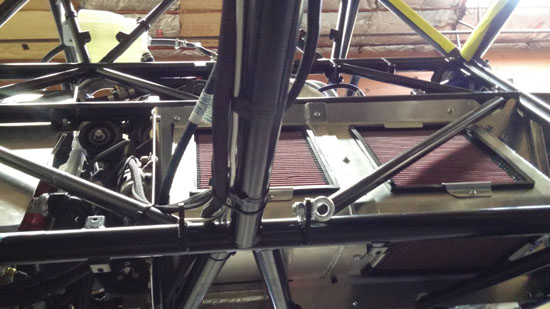

The LSA is a super tight fit in the D2 chassis. The D5, which will use the LSA (or LT4?) as standard, will have an extra 6" of wheelbase, with the extra room split evenly between engine compartment and passenger compartment. So yes, in my customary fashion, we’re also doing D5 development here 🙂

All this has to be put in the context of the fact that we’re also scrambling to complete the first Sector111 Drakan car, build the next 4, order and make parts, finish D1 maintenance, make progress on D1 trailer, take apart and send off to powdercoat and paint the turbo D4, make progress on the Stiletto, machine and ship several different uprights orders, and a host of other projects. And right now there are just five of us doing all the above at once. Fun.