Things are moving right along. We are getting very good response from sponsors for the effort, both individual and commercial, which is a great help (and added motivation!). Thank you very much for the support!

The build on the race car continues. Lots of not-so-visible stuff like plumbing. Suspension is fabricated and will be installed shortly. Stll figuring out the intake but it’s getting there.

The intake tube requires a 6″ straight section for the airflow meter to work properly which is a challenge. We are bascially making a custom airbox behind the seats with multiple filter panels to get us as much filter area as possible.

While the race car is being built we are updating our normally aspirated demo D2 with a drysump system for the engine, revised front suspension arms (to change steering effort) and bigger brakes. So far we’ve been running the demo on R888 and NT01 tires and with those the wet sump is right on the edge. The car pulls 1.4g sustained on this level of tire (1.7g peak) and there are some logged oil pressure drops to below 20 psi. Hoosier is supplying us with the latest A7 rubber for the race and on the sticky tires we expect well over 2.0g cornering. We want to start testing with the race tires as soon as possible, hence the drysump upgrade for the demo.

The car last ran on Saturday (I think it was something like 50th trackday for it) and now it looks like this, with engine and transmission out:

Testing is planned to resume on the 10th with the updates installed. For the brakes I still have to machine custom rotor hats and caliper brackets. Suspension arms are made already, just need to be installed.

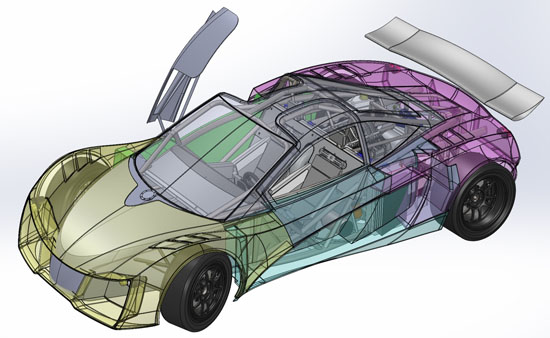

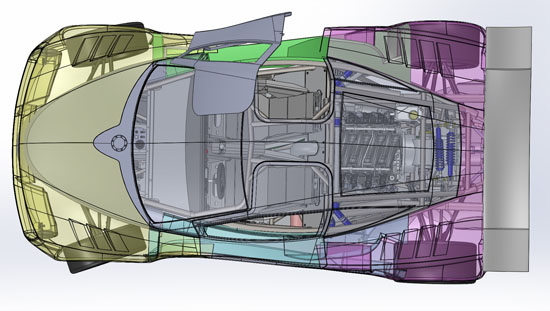

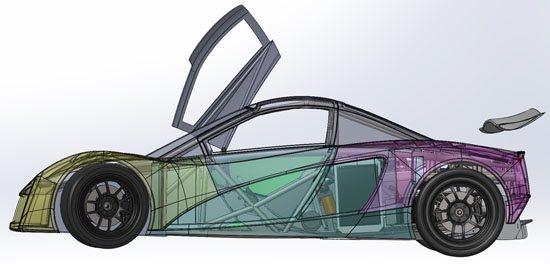

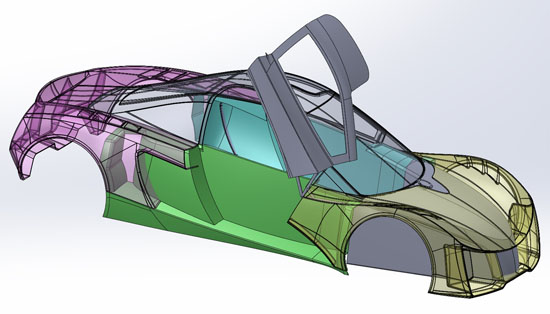

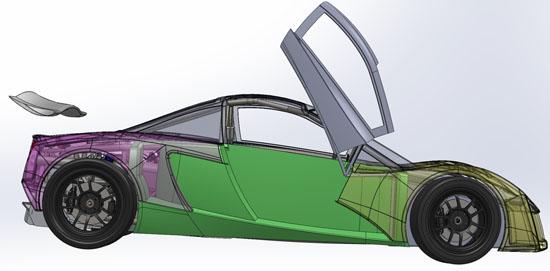

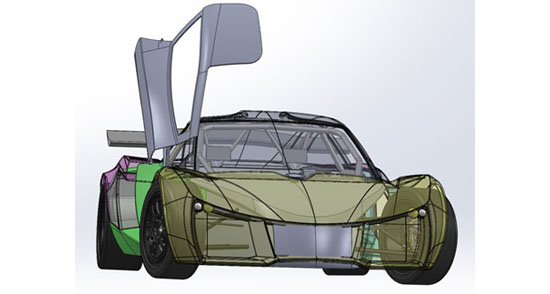

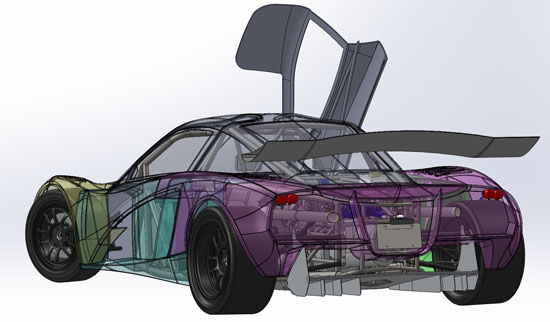

In parallel the new bodywork is progressing as well. This is the stage where all the pesky little details get worked out – how the various panels are split up, how they interface to each other, how each is molded. Door hinges, coupe vs roadster configuration, access to components – all of this is as 3D puzzle wth many interactions. Click on the first picture for a larger version.

We are currently looking at three different ways to get the plugs (master patterns) made from which we can then pull molds. The tradeoffs are time, cost and technological unknowns – 3D printing is one potential method but at this size it’s not a proven technology and costs are not known. 5-axis CNC machining of foam plugs is something we’ve done before but it requires farming it out and the costs are fairly high. Breaking up molds into pieces that are machinable on a 3-axis router requires more CAD work but it’s the most accessible and lowest cost approach. I’m now talking with various vendors as we are in the final stretch for the design. A decision will have to be made soon.