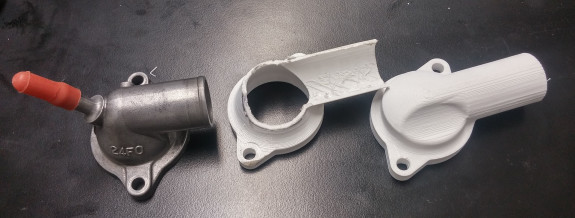

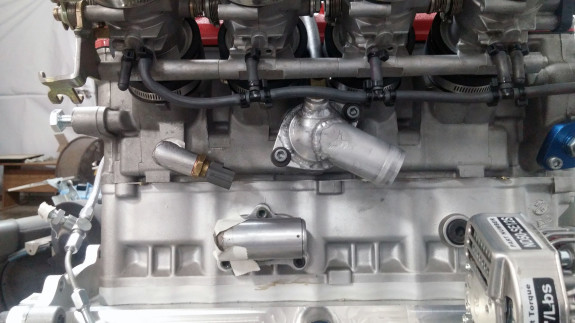

I mentioned I’d talk about the D1PPS engine – it’s been an ongoing story and below are some of the highlights. As with everything we do, packaging is extremely tight. I had to take Hartley’s compact intercooler and move it closer to the block by using custom 15 degree elbows to mount the throttle bodies to the head. This in turn has created a number of problems – like having to turn the water temp sensor 90 degrees and make a lower profile thermostat housing. The former was fairly sraightforward, after we figured out what the threads are, got the rare tap and die, then fine-tuned the depth so that the adapter sealed in the right orientation.

The thermostat housing was considerably more work. First, Jay made a CAD model of the original, 3D printed it on his printer, and modified it until it fit. Then he made a new model and printed that to make sure all is happy.

We briefly entertained the notion of getting it 3D printed in metal, until we got the price – $750 was the cheapest quote and others were much higher. Guess metal 3D printing is not quite yet a mainstream production technology except for aircraft. Can’t wait until it’s more accessible, the possibilities are very exciting.

Another option we looked at is a high-temperature plastic. We can’t print with the high-temp glass reinforced plastics that OEMs use (injection molding those). But there was a material that looked promising. Unfortunately an oven test at 300F dashed those hopes.

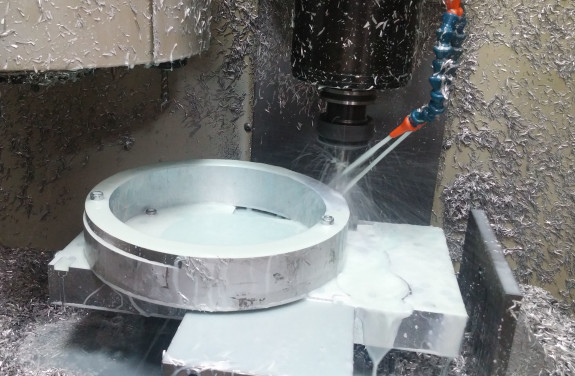

This would actually be a fun part to try on the mill but it was busy with lots of other things, so Tristan went the lathed-and-welded route.

Now all is good – clearance is clearance.

In the meantime we picked up an ECU, a wiring harnes, and got a set of high-flow injectors from InjectorDynamics. Despite the fact that they flow about 3x the stock Hayabusa units, they are very controllable at low flows and idle just fine. We used 725cc units on the Turbo D4 but went with 1,000cc ones for this application.

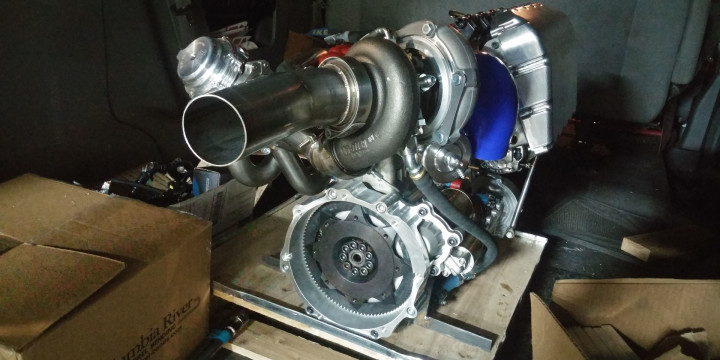

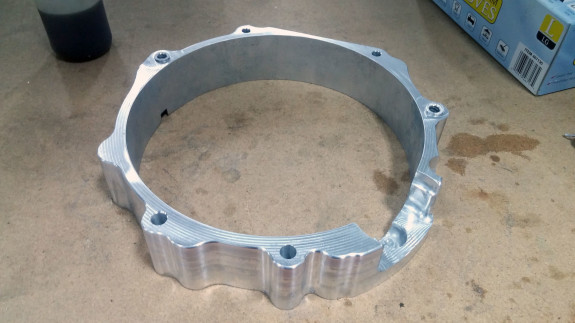

One of the many challenges is mounting this engine to the Dyno. George Dean at GDRE has been working with Hartley for some time now and has everything needed to mount a Bolt4 engine. This one is an earlier H2 so it’s different in many ways, including the transmission interface. The modifications made already have brought this engine closer to the new spec, so the next logical step is to make it installation compatible. So I set about designing and making an interface plate to achieve this. Designing took some doing, making even more so. The now familiar dimensional challenge of the machine was a factor here as well. But I got it done.

Tomorrow I’m driving the engine up to Seattle and we’ll see how it goes.

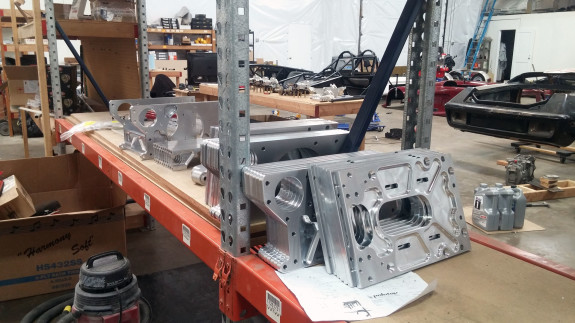

In the meantime many other things are happening. The suspension box parts are off to anodizing.

Some really exciting stuff happening on the D2RS too, but that’s for the next post.